If your Hako B45 floor scrubber is leaving puddles, it’s frustrating and counterproductive. As a leading manufacturer of floor squeegee blades, we’ve identified common causes and solutions—many tied to the quality of rubber suppliers and blade maintenance. Let’s dive in.

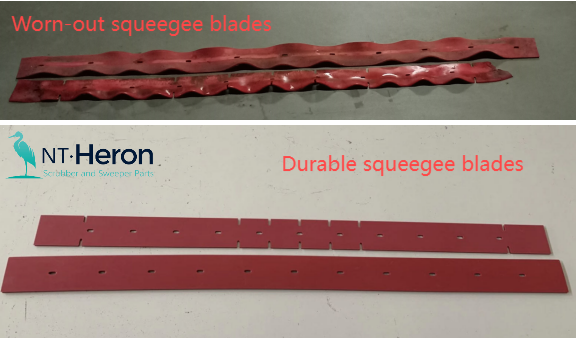

Worn or Damaged Rubber Blade

Time-Saving InstallationThe rubber blade is the heart of your squeegee. Over time, friction and chemical exposure degrade the rubber, reducing its ability to seal against the floor. If your blade is cracked, warped, or thin, it’s time for a replacement.

Fix: Source high-quality rubber from trusted sheet rubber suppliers. Premium rubber resists wear and maintains flexibility.

Incorrect Blade Angle or Pressure

Improper blade alignment prevents even contact with the floor. The Hako B45 relies on precise angles to channel water into the recovery tank.

- Fix: Adjust the blade angle to 45 degrees. Check the scrubber manual or watch the video tutorial below.

- Video: How to Adjust Your Hako B45 Squeegee Blade

Debris or Contaminants on the Blade

Dirt, grease, or small debris can lodge under the blade, creating gaps.

- Fix: Clean the blade daily. Use a mild detergent and inspect for embedded particles.

Uneven or Textured Flooring

Rough surfaces prevent the blade from creating a tight seal.

- Fix: Use a softer rubber compound. Collaborate with rubber suppliers near me to customize blades for textured floors.

- External Link: Hako Official Floor Compatibility Guide

Low-Quality Rubber Material

Not all rubber is equal. Cheap blends harden or crack quickly, leading to leaks.

- Fix: Partner with reputable sheet rubber suppliers specializing in industrial-grade materials. Our guide below explains how to choose the right rubber.

- Internal Link: How to Select Industrial Rubber

How to Find Reliable Rubber Suppliers Near Me

Quality rubber is non-negotiable. Here’s how to vet suppliers:

- Certifications: Ensure ISO or ASTM compliance.

- Customization: Can they tailor rubber thickness/hardness?

- Local Partnerships: Nearby rubber suppliers reduce shipping delays.

Pro Tip: Maintenance Schedule

- Inspect blades weekly.

- Replace blades every 3–6 months (or sooner in high-traffic areas).

- Lubricate pivot points monthly.

Need Premium Rubber Solutions?

As trusted sheet rubber suppliers, we provide OEM-certified materials for Hako B45 blades. Contact us for samples or expert advice.

Learn more: Global Rubber Supplier Directory

You’ll eliminate puddles and boost efficiency by addressing rubber quality, maintenance, and supplier partnerships. Don’t let a worn blade slow you down—invest in solutions that last!