Mining is a tough and demanding industry. With extreme conditions, heavy-duty machinery, and continuous operations, the materials used in mining equipment must be able to withstand significant wear and tear. One such material that has gained popularity for its resilience and performance in mining equipment is natural rubber. Specifically, natural rubber sheets offer protection and longevity to various types of mining equipment.

In this blog, we’ll explore which types of mining equipment require natural rubber sheets, the benefits of using them, and how NTheron Limited’s products can help mining companies achieve maximum operational efficiency.

Why Natural Rubber Sheets Are Crucial in Mining

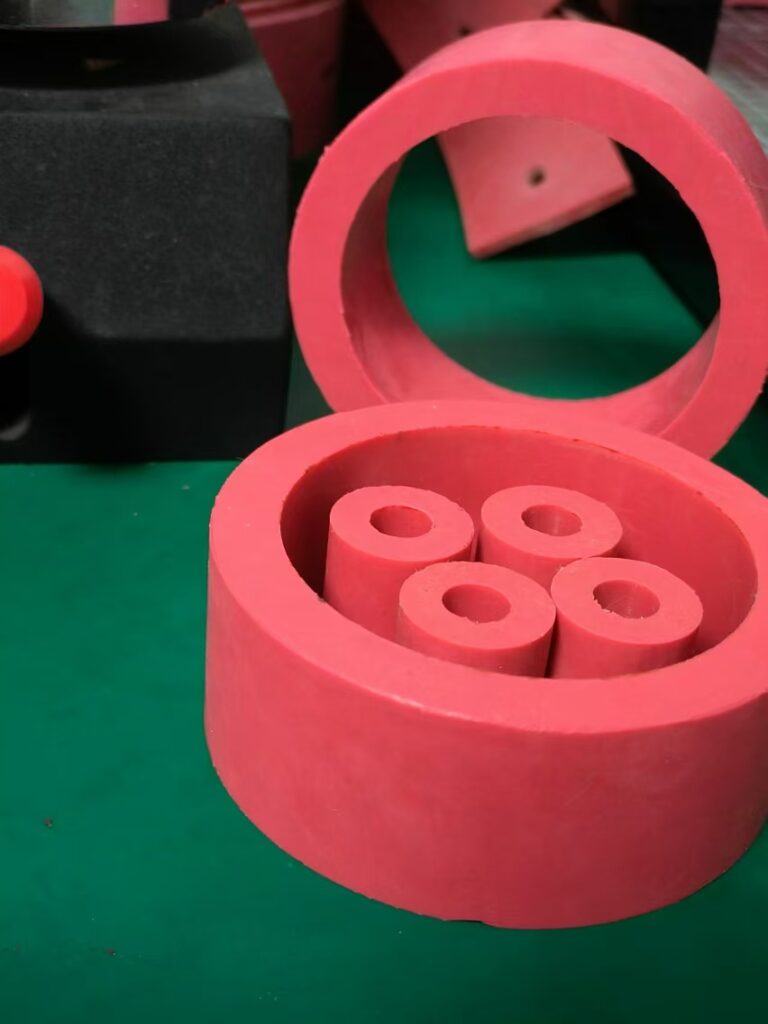

Before diving into the specific equipment, let’s take a closer look at why natural rubber is such a vital material in mining operations. Natural rubber is highly elastic, durable, and resistant to wear, making it ideal for applications where constant movement, abrasion, and exposure to harsh elements occur.

Key benefits of natural rubber sheets include:

- Resistance to abrasives: In mining, equipment comes in contact with a wide variety of sharp and abrasive materials. Natural rubber can withstand this without significant damage.

- Shock absorption: Natural rubber is known for its ability to absorb shocks and vibrations, which helps in protecting heavy machinery.

- Flexibility: The elasticity of natural rubber ensures that it can be molded to fit various shapes and components.

- Chemical resistance: Many mining operations involve exposure to chemicals, making rubber sheets an ideal choice for providing a protective barrier.

Considering these benefits, mining equipment often employs natural rubber sheets for linings, seals, and wear-resistant surfaces.

Conveyors and Belt Liners

One of the most important pieces of equipment in mining operations is the conveyor belt. Used to transport minerals and raw materials, conveyor belts are exposed to constant movement, friction, and heavy loads. To protect both the conveyor belts and the materials they carry, natural rubber sheets are often used as belt liners or protective covers.

These rubber sheets provide excellent abrasion resistance and prevent the materials being transported from damaging the belts. By using natural rubber sheets for belt liners, mining companies can reduce downtime and extend the lifespan of their conveyor belts.

Check out our range of high-quality rubber sheets for conveyor belts at NTheron Limited.

Vibrating Screens

Vibrating screens are another key equipment in the mining sector. Used to sort and separate materials, they are subject to extreme wear. The constant vibration can cause significant damage to the metal surfaces and components of the screens.

To counteract this, natural rubber sheets are often used to line the vibrating screens. This not only protects the metal surface but also reduces noise and absorbs vibration, which can improve operational efficiency and extend the equipment’s service life.

For more details on how vibrating screens work in mining, refer to this guide from Mining Technology.

Crushers and Mills

Mining crushers and mills are responsible for breaking down large chunks of raw material into smaller, more manageable sizes. These machines generate a tremendous amount of force, which can quickly wear out unprotected surfaces.

Natural rubber sheets are commonly used as linings inside crushers and mills to protect the inner surfaces from damage caused by crushing abrasive materials. The flexibility and toughness of rubber prevent the wear and tear that would otherwise compromise the equipment’s performance.

Explore our range of natural rubber sheet solutions for crushers and mills.

Slurry Pumps and Pipes

Slurry pumps and pipes are essential for transporting slurries—liquids containing fine particles of materials such as minerals, ores, or coal—throughout mining operations. These slurries can be highly abrasive, which puts considerable stress on the pump interiors and pipe walls.

Natural rubber sheets are widely used to line slurry pumps and pipes to protect against abrasion, corrosion, and general wear. Rubber’s natural elasticity allows it to withstand the pressures and impacts typical in these applications.

Learn more about slurry pumps and how they work on this engineering resource.

Chutes and Hoppers

Chutes and hoppers are used to funnel mined materials from one part of a processing plant to another. Due to their constant exposure to falling rocks, minerals, and ores, chutes and hoppers are prone to excessive wear.

By using natural rubber sheets as lining materials, mining companies can extend the lifespan of their chutes and hoppers. The rubber sheets cushion the impact of materials and reduce the likelihood of damage to the equipment.

Protect your chutes and hoppers with durable rubber sheet linings from NTheron Limited.

Tanks and Agitators

Tanks and agitators are crucial in the mineral processing stages of mining. They are used to mix chemicals with ore to extract valuable metals. Given the constant chemical exposure, these tanks need protection from corrosion, and natural rubber sheets provide an ideal solution.

Rubber-lined tanks and agitators ensure that the chemicals used in processing do not corrode the metal surfaces, ensuring the safety and longevity of the equipment.

For further insights into tank linings, check out this comprehensive article from Process Worldwide.

Flotation Cells

Flotation cells are used to separate minerals from waste using bubbles and chemicals. These cells are exposed to highly abrasive materials and aggressive chemical solutions, making them vulnerable to wear and tear. Natural rubber linings protect flotation cells as a barrier between the cell walls and the abrasive materials.

This helps to extend the service life of the flotation cells and reduce the need for frequent maintenance and repairs.

Extend the lifespan of your flotation cells with our high-performance rubber linings.

Conclusion

Natural rubber sheets are critical for protecting mining equipment in harsh environments. Whether it’s conveyors, crushers, slurry pumps, or flotation cells, rubber’s durability, elasticity, and abrasion resistance make it the material of choice for many applications.

For mining companies looking to enhance the longevity and performance of their equipment, NTheron Limited provides a range of high-quality rubber sheet products that can be tailored to meet the needs of any mining operation.

Visit our website to learn more about NTheron Limited’s products and how we can help you protect your mining equipment and reduce maintenance costs.