In today’s industrial landscape, rubber sheets play a critical role in a wide variety of applications. From gaskets and seals to floor covering and insulation, these flexible materials are important. But have you ever wondered how commercial rubber sheets are manufactured? In this article, we will certainly discover the interesting procedure behind industrial rubber sheet manufacturing, clarifying the techniques and materials involved.

Rubber sheet manufacturing is a complicated procedure that involves numerous steps, each crucial to ensuring the end product’s quality and performance. Suppliers have to select the appropriate type of rubber, mix it with numerous additives, and shape and heal the product to develop long-lasting rubber sheets.

Kinds Of Rubber Used

At first, Rubber sheets can be made from natural or artificial rubber, each offering distinctive properties. All-natural rubber is derived from the latex sap of rubber trees, while synthetic rubber is generated via chemical processes. Usual types of synthetic rubber utilized in industrial applications include:

- Neoprene: Understood for its outstanding chemical security and resistance to weathering.

- EPDM (Ethylene Propylene Diene Monomer): Offers impressive resistance to heat, ozone, and aging.

- Nitrile Rubber: Recognized for its oil resistance and durability.

Suppliers pick the type of rubber based on the intended use of the rubber sheets and the specific demands of the application.

The Production Refine

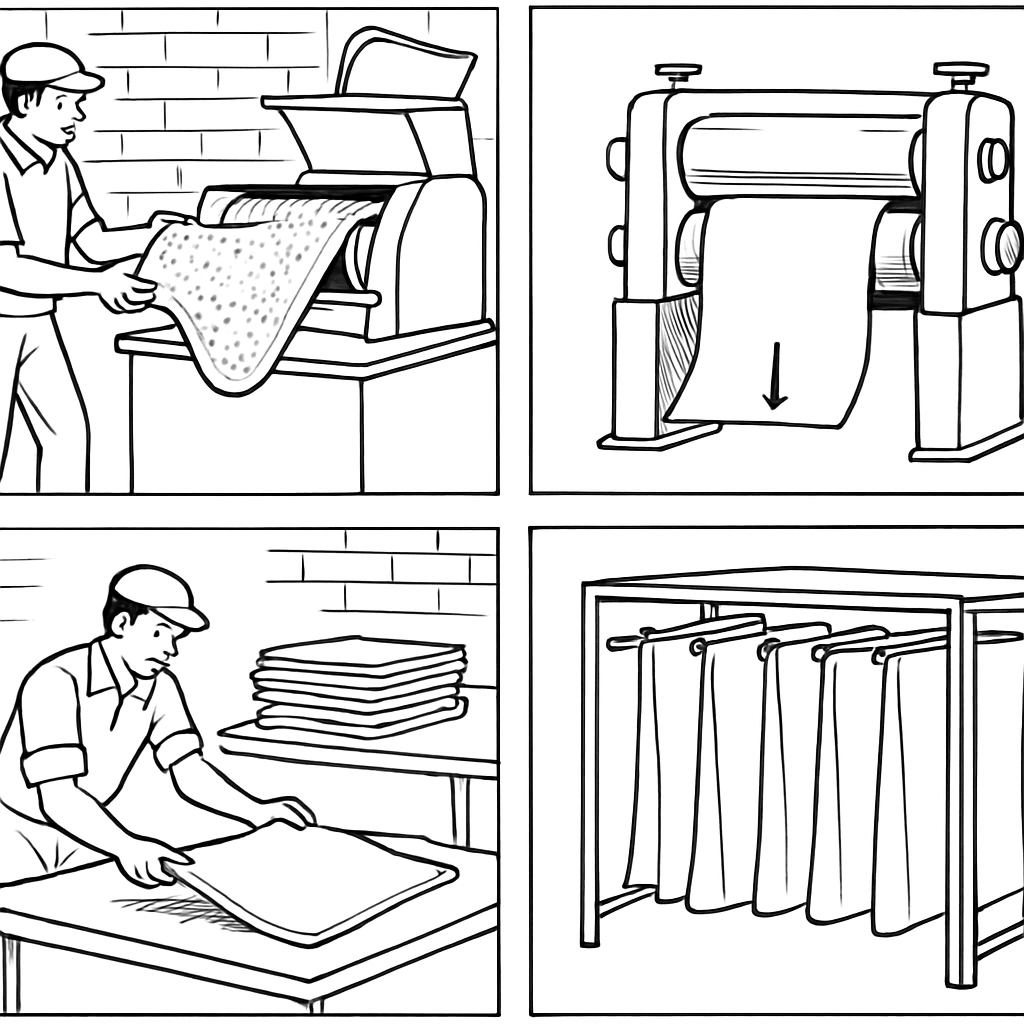

And the process of manufacturing commercial rubber sheets can be broken down into several vital phases:

Worsening

Compounding is the first step in rubber sheet production. It involves blending raw rubber with numerous additives to boost its residential or commercial properties. These ingredients can consist of fillers, healing agents, antioxidants, and accelerators. The substance is thoroughly developed to satisfy the preferred requirements, such as hardness, versatility, and resistance to warm or chemicals.

Blending

As soon as the substance is prepared, it experiences a blending procedure. This normally happens in a big mixer, where the rubber substance is completely combined to ensure harmony. The blending procedure is important for achieving regular high quality in the final product.

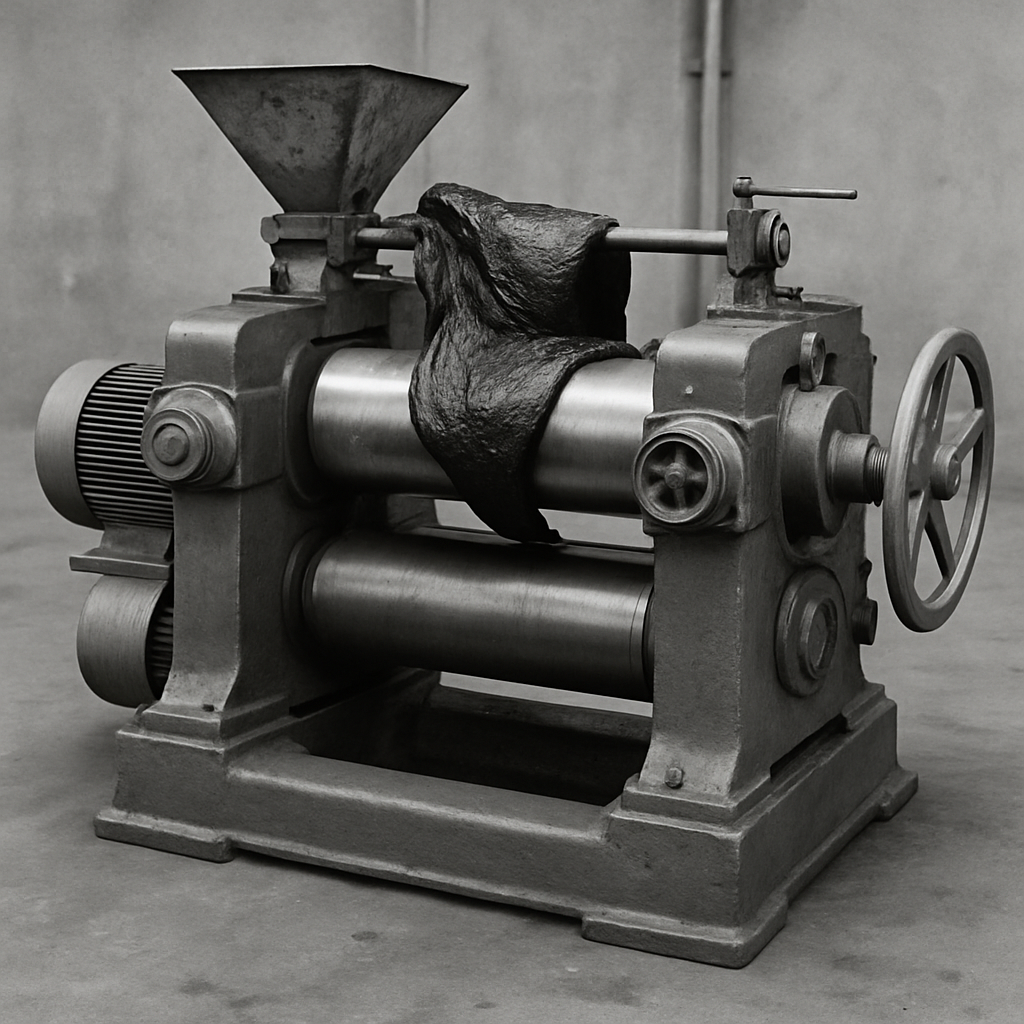

Calendaring

Calendaring is an essential action in forming the rubber compound into sheets. During this procedure, the compound is fed via a series of rollers that squash it into thin, uniform sheets. The density of the sheets can be readjusted based on the designated application. Calendaring not just shapes the rubber but also enhances its surface finish.

Vulcanization

Vulcanization is a critical step that involves healing the rubber sheets to boost their stamina and elasticity. This is accomplished by heating the rubber sheets in the presence of sulfur or other healing agents. Vulcanization creates cross-links between the rubber particles, changing the product into a long-lasting and durable product.

Reducing and Ending

After vulcanization, the rubber sheets are cut into the desired sizes and shapes. Makers often utilize precision cutting tools to ensure precision. The sheets might likewise go through additional finishing procedures, such as cutting or surface treatment, to meet specific customer requirements.

Quality Control and Screening

Most importantly, industrial rubber sheet production puts a solid focus on quality assurance and screening. Manufacturers carry out strenuous tests to make sure that the rubber sheets fulfill market criteria and consumer requirements. These tests might consist of:

- Tensile Toughness Testing: Measures the sheet’s capability to stand up to extending without breaking.

- Compression Set Screening: Evaluates the sheet’s ability to go back to its initial form after compression.

- Aging Tests: Examine exactly how the rubber sheets perform under different environmental problems.

Applications of Industrial Rubber Sheets.

Industrial rubber sheets have a vast array of applications throughout different markets. Some usual uses include:.

- Gaskets and Seals: Rubber sheets are used to produce gaskets and seals for equipment and tools, providing a dependable barrier against leaks and impurities.

- Flooring and Matting: Rubber sheets supply excellent slip resistance and cushioning, making them perfect for floor covering in industrial and business setups.

- Insulation: Rubber sheets offer reliable thermal and electric insulation, making them ideal for use in electrical cabinets and heating and cooling systems.

Picking the Right Rubber Sheet Distributor.

When sourcing rubber sheets for your industrial needs, it’s vital to choose a reputable provider. Consider the following aspects when choosing a rubber sheet provider:.

- Quality Control: Ensure that the provider abides by rigorous quality assurance procedures and provides items that fulfill industry requirements.

- Customization Options: Look for a provider that supplies modification options to satisfy your particular requirements, such as dimension, density, and product composition.

- Track record and Experience: Choose a distributor with a proven track record and comprehensive experience in the market.

By partnering with a reputable rubber sheet vendor, you can guarantee that you receive high-quality items that satisfy your demands and contribute to the success of your projects.

Verdict.

So industrial rubber sheet manufacturing is a sophisticated process that entails careful choice of products, precise mixing, forming, and treating. The resulting rubber sheets are versatile and important elements in numerous sectors, from making to building. By recognizing the manufacturing process and selecting the right vendor, you can make enlightened choices for your industrial applications. Rubber sheets continue to be a vital source in the modern-day commercial landscape, providing resilience, flexibility, and integrity in numerous applications.