Floor scrubber hoses are vital for keeping large spaces clean, carrying water to brushes, and sucking up dirty water. Neglecting their maintenance can lead to clogs, leaks, and costly downtime. This article outlines five practical tips to keep your hoses in top shape, helping businesses save time and money while ensuring clean, safe floors. Whether you’re a cleaning service owner or a distributor, these tips will help you maintain your equipment effectively.

Why Maintenance Matters

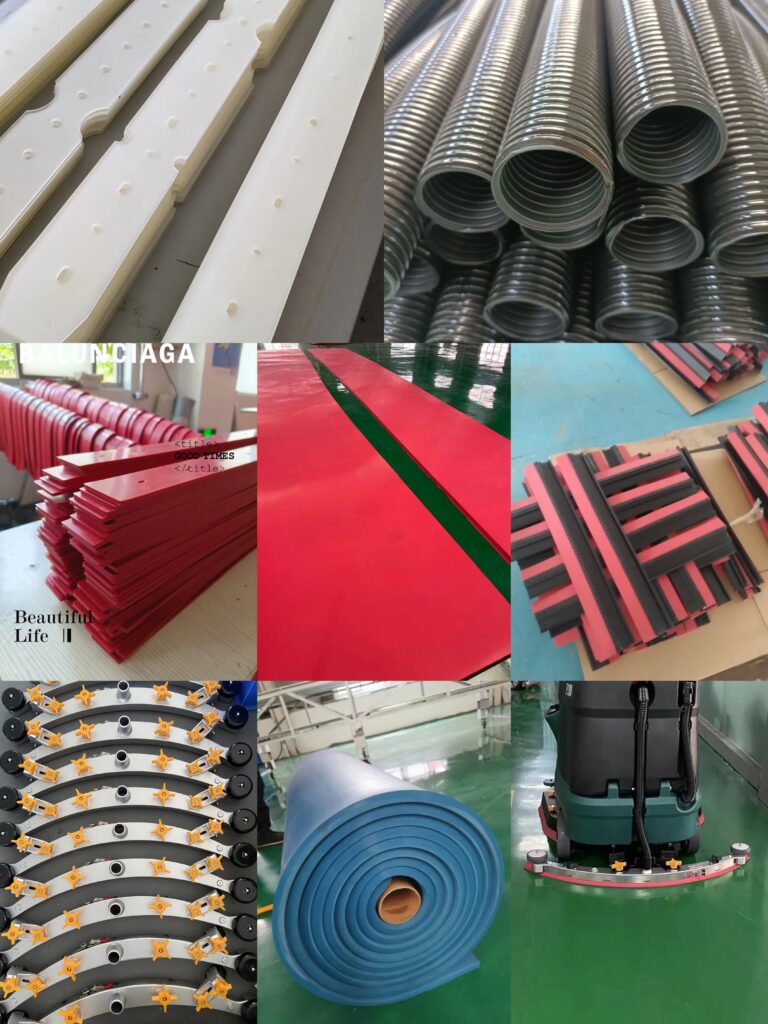

Floor scrubbers are essential for maintaining clean, safe floors in commercial and industrial settings. The hoses, often made of durable materials like rubber or reinforced plastic, are integral to the machine’s operation. However, they are susceptible to wear and tear from regular use, exposure to cleaning chemicals, and environmental factors. Maintenance is crucial for machine efficiency and safety, as clogged or leaking hoses can leave wet spots, increasing the risk of slips and falls, as noted by the Occupational Safety and Health Administration (OSHA guidelines).

For businesses, maintaining hoses reduces repair costs and downtime, while for distributors, offering reliable parts like hoses enhances customer trust and loyalty. NT.Heron, a supplier of floor scrubber accessories including hoses, squeegee blades, and parts, benefits from highlighting maintenance practices to attract foreign wholesalers seeking quality equipment.

Detailed Tips for Maintaining Floor Scrubber Hoses

Check for Clogs and Blockages Regularly

Description: Clogs and blockages in hoses can disrupt water flow, leading to poor cleaning performance or machine damage. Debris such as dirt, hair, or gunk can accumulate, especially in high-use environments.

How to Implement: Perform a visual inspection weekly or after each use, depending on usage frequency. Look for visible debris or kinks in the hoses. To test for blockages, flush the hoses with clean water and observe if the water flows freely. If there’s resistance, use a soft brush or backflush with a hose to clear the obstruction, ensuring no sharp tools are used to avoid puncturing the hose.

Frequency and Benefits: Regular checks, at least once a week, prevent performance issues and extend hose life. This practice is supported by CleanFreak.com’s preventative maintenance tips, which highlight the importance of clearing hoses to reduce service costs (CleanFreak.com maintenance tips).

Visual Aid Suggestion: Include a photo after this section showing someone inspecting a hose for clogs, with a caption like “Checking for blockages ensures smooth operation.”

Flush Hoses with Clean Water After Use

Description: Flushing hoses removes residual cleaning solution, dirt, or debris that can build up inside, potentially causing clogs or corrosion over time. This is particularly important after using chemical cleaners, which can leave a gel-like substance if not cleared, as noted by Imperial Dade (Imperial Dade maintenance guide).

How to Implement: After each cleaning session, drain the recovery and solution tanks. Attach a hose to the machine’s drainage port and run clean water through the system until it comes out clear. This process, often called backflushing, dislodges any remaining debris and prevents sludge buildup.

Benefits: Regular flushing prevents odors, mold, and mildew, ensuring the machine is ready for the next use. It also protects the hose material from chemical degradation, extending its lifespan.

Visual Aid Suggestion: Include a video after this section demonstrating the flushing process, with a caption like “Flushing hoses keeps them clean and functional.”

Inspect Hoses for Cracks or Leaks

Description: Cracks and leaks in hoses can lead to water loss, reducing the machine’s ability to clean effectively and potentially damaging floors or surrounding areas. Wear and tear can occur from frequent use, pressure, or exposure to harsh chemicals.

How to Implement: Conduct a visual inspection during routine maintenance, looking for cracks, bulges, or discoloration. Run your hand along the hose to feel for soft spots or abnormalities. For a more thorough check, pressurize the hose (if possible) and look for leaks. CleanLink recommends checking hoses and seals for cracks or signs of wear after each use (CleanLink maintenance tips).

When to Replace: Replace any hose showing signs of damage immediately to prevent further issues. NT. Heron offers high-quality replacement hoses, ensuring compatibility and reliability (NT.Heron hose products).

Visual Aid Suggestion: Include a photo after this section comparing a damaged hose to a good one, with a caption like “Spot the difference: Damaged vs. intact hoses.”

Properly Store the Machine to Protect the Hoses

Description: Proper storage prevents hoses from being damaged by environmental factors like extreme temperatures, moisture, or physical pressure, which can cause kinks or cracks. Storing the machine incorrectly can lead to premature hose failure, increasing maintenance costs.

How to Implement: Store the machine in a dry, clean area away from direct sunlight and moisture, as recommended by Bortek Industries (Bortek storage tips). Ensure the machine is in the upright position with hoses not kinked or twisted. For long-term storage, drain all tanks and hoses completely to prevent freezing or fungal growth, especially in colder climates.

Benefits: Proper storage extends hose life and protects the investment in your equipment, particularly important for distributors supplying to foreign markets where storage conditions may vary.

Visual Aid Suggestion: Include a photo after this section showing a properly stored floor scrubber with hoses managed correctly, with a caption like “Correct storage prevents hose damage.”

Handle Hoses Carefully to Avoid Damage

Description: Rough handling, such as kinking, twisting, or stepping on hoses, can cause premature wear and tear, reducing their lifespan and affecting machine performance. This is particularly relevant during operation and storage, where hoses can be accidentally damaged.

How to Implement: Train operators to avoid kinking or twisting hoses during use, ensuring they are kept straight and untangled. Use hose reels or organizers to manage hoses properly, especially during storage. Avoid dragging hoses over rough surfaces or stepping on them, which can cause internal damage.

Benefits: Careful handling extends hose life, reducing the need for frequent replacements and maintaining machine efficiency. This practice is crucial for businesses aiming to minimize maintenance costs and for distributors to ensure customer satisfaction.

Visual Aid Suggestion: Include a video after this section showing proper handling of hoses during machine operation, with a caption like “Handle hoses with care for longer life.”

Discussion and Implications

These five tips are practical and actionable, designed for business owners, cleaning service operators, and distributors. For NT.Heron, emphasizing hose maintenance aligns with their goal of attracting high-quality foreign wholesalers and distributors by showcasing expertise in floor scrubber accessories. Quality hoses, like those offered by NT. Heron, complements these maintenance practices, ensuring reliability and performance in diverse markets.

The tips also address safety concerns, such as preventing wet floors from leaks, which aligns with OSHA guidelines (OSHA slip-fall prevention). For distributors, offering maintenance advice alongside quality parts can build trust and encourage repeat business, particularly in international markets where equipment reliability is paramount.

Comparative Analysis

A table comparing common hose maintenance issues and solutions can illustrate the importance of these tips:

| Issue | Cause | Solution |

|---|---|---|

| Clogged hoses | Debris buildup | Check and flush regularly |

| Leaking hoses | Cracks or wear | Inspect and replace damaged hoses |

| Reduced water flow | Residue or blockages | Flush with clean water after use |

| Kinked or twisted hoses | Improper handling or storage | Handle carefully and store properly |

| Premature hose failure | Environmental damage | Store in dry, clean area |

This table highlights how each tip addresses specific problems, reinforcing the need for regular maintenance.

Conclusion

Maintaining floor scrubber hoses is essential for efficient operation and long-term cost savings. By checking for clogs, flushing with clean water, inspecting for damage, storing properly, and handling carefully, businesses can ensure their equipment performs at its best. For distributors and wholesalers, partnering with suppliers like NT. Heron, which offers high-quality hoses and parts, enhances reliability and customer satisfaction. Visit NT.Heron for more information on floor scrubber accessories and maintenance support.