As a distributor of floor scrubbers, understanding the floor scrubber parts that keep these machines running efficiently is key to meeting client demands and reducing returns. Here’s a breakdown of the most vital parts, their functions, and why sourcing high-quality replacements matters.

Squeegee Blades: The Unsung Heroes of Dry Floors

Firstly, Squeegee blades are crucial for leaving floors streak-free. So, Low-quality blades wear out quickly, leading to water residue and customer complaints. Opt for durable rubber or polyurethane blades (like our high-quality squeegee blades) that resist cracks and offer 6–12 months of service.

Pro Tip: Pair blades with adjustable tension systems to extend lifespan. Contact rubber manufacturer here>>>.

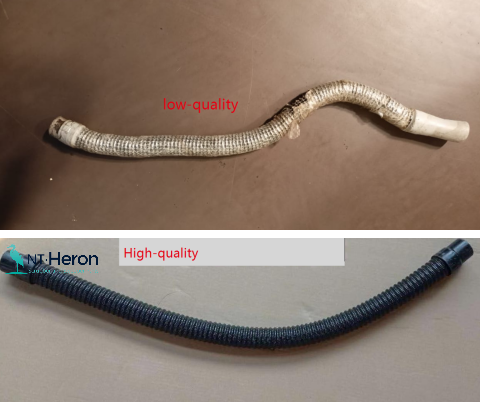

Hoses: The Lifeline for Water and Chemical Flow

Secondly, clogged or cracked hoses disrupt suction and chemical delivery. Distributors should prioritize abrasion-resistant hoses (explore our scrubber hoses) designed for high-pressure environments. Ensure compatibility with both hot and cold water to cater to diverse scrubber models.

Brushes and Pads: Customization Wins Clients

Thirdly, different floor types (concrete, epoxy, tile) require specific brush stiffness. Stock ceramic, nylon, and hybrid brushes to meet varied needs. Highlight eco-friendly options for clients prioritizing sustainability.

Motors and Batteries: Powering Reliability

Fourthly, Frequent motor failures damage your reputation. Source OEM-compatible motors and lithium-ion batteries with fast charging. Link to industry benchmarks (external link) to validate performance claims.

Solution Tanks and Filters: Avoid Contamination

Fifth, corroded tanks or dirty filters lead to breakdowns. Recommend stainless steel tanks and replaceable filters to minimize downtime.

Why Quality Parts Matter for Distributors

- Lower Return Rates: Durable parts reduce warranty claims.

- Higher Customer Retention: Reliable components = loyal clients.

- Competitive Edge: Position yourself as a knowledge leader with guides like Floor Scrubber Maintenance.

Maintenance Tips to Share with Clients

- Weekly Inspections: Check squeegee blades and hoses for wear.

- Clean Filters Biweekly: This prevents debris buildup.

- Use Genuine Parts: Avoid cheap imitations that void warranties.

If you want to learn more, please check below :

Tips for quick fixes& replacements for broken hoses >>>

10 recommendations for commercial floor scrubber maintenance>>>.

Final Takeaway:

So stocking premium floor scrubber parts like squeegee blades and hoses isn’t just about sales—it’s about building trust. Partner with manufacturers who provide detailed specs, CAD files, and fast shipping (like our global logistics solutions).

At last, by educating your clients and offering reliable parts, you’ll become their go-to resource in the competitive cleaning equipment industry.