Maintaining clean and safe floors can be a challenge in industries where oils, greases, and other stubborn contaminants are commonplace. However, businesses can effectively tackle these tough cleaning tasks with the right equipment, such as floor scrubbers equipped with polyurethane squeegee blades. This article guide will explore the benefits known for its resistance to oils and greases, and squeegee blades, discuss their applications, and provide practical tips for selecting and maintaining these essential components of floor scrubber machines.

Composition:

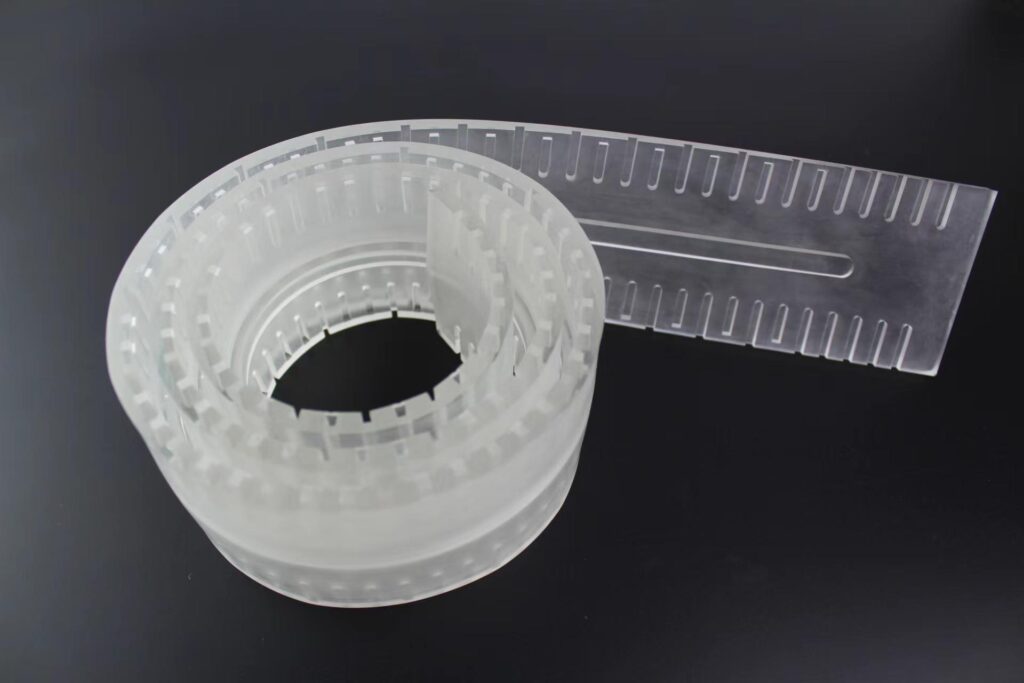

Polyurethane is a polymer composed of organic units joined by urethane links.

Industry reports highlight the importance of using durable and efficient cleaning equipment in industrial environments. According to a report by Grand View Research, the global industrial cleaning market is expected to reach $70.62 billion by 2027, driven by factors such as increasing awareness of hygiene and safety standards. Another study by ResearchAndMarkets emphasizes the growing demand for specialized cleaning solutions that can effectively remove oils, greases, and other contaminants from floors and surfaces.

Properties:

- Flexibility: Can be formulated to be either rigid or flexible, depending on the application.

- Durability: Extremely durable and resistant to abrasion, impact, and tearing.

- Temperature Resistance: Typically stable from -40°C to 80°C, with some formulations able to withstand higher temperatures.

- Water Resistance: Good water resistance, though not as impermeable as neoprene.

- Elasticity: Offers high elasticity and can be tailored to specific elasticity requirements.

Applications:

Foam insulation, seals, gaskets, wheels and tires, coatings, adhesives, and various automotive components.

- Automotive Manufacturing: Polyurethane blades are ideal for removing oils, greases, and lubricants commonly found in automotive assembly plants and repair facilities.

- Food Processing: Polyurethane squeegee blades are used in food processing plants to maintain clean and hygienic floors, even in areas exposed to oils and food residues.

- Warehousing and Distribution: Polyurethane is effective for cleaning warehouse floors and loading docks where spills and leaks are frequent occurrences.

Advantages:

- Highly customizable in terms of hardness, flexibility, and other properties.

- Excellent load-bearing capacity and mechanical properties.

- Good resistance to oil, grease, and solvents.

Disadvantages:

- Can degrade when exposed to certain chemicals and UV light without proper additives.

- Generally more expensive than neoprene, especially in specialized formulations.

Practical Tips for Selecting Polyurethane Squeegee Blades

Choosing the right polyurethane squeegee blades involves considering several factors as below:

- Blade Hardness: Polyurethane blades are available in different hardness levels, ranging from soft to hard. Soft blades offer better flexibility and conformability, while harder blades provide superior durability and resistance to wear.

- Width and Length: Select the appropriate blade width and length to match the size of your floor scrubber machine and the cleaning area.

- Compatibility: Ensure that the polyurethane blades are compatible with your specific floor scrubber model. Check compatibility charts provided by manufacturers or consult with suppliers for guidance.

- Thickness: Thicker blades offer increased durability and longevity, but may sacrifice some flexibility. Choose the thickness that best balances durability and performance for your application.

- Manufacturer Reputation: Purchase polyurethane squeegee blades from reputable manufacturers known for their quality and reliability. Look for manufacturers with a proven tracking record of producing high-performance cleaning equipment components.

Maintenance and Care Tips

Proper maintenance is essential to maximize the lifespan and performance of polyurethane squeegee blades:

- Regular Cleaning: After each use, clean the squeegee blades thoroughly to remove any debris or contaminants. Use water and a mild detergent to clean both sides of the blade.

- Inspection for Wear and Tear: Regularly inspect the blades for signs of wear, such as cuts, tears, or uneven edges. Replace worn or damaged blades promptly to maintain cleaning efficiency.

- Proper Storage: Store squeegee blades in a clean, dry environment away from direct sunlight and extreme temperatures. Avoid storing them in areas where they may be exposed to chemicals or solvents that could degrade the material.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s advice for maintenance and replacement methods.

Polyurethane squeegee blades are the ultimate solution for removing oils, greases, and other stubborn contaminants from industrial floors. Their exceptional resistance, flexibility, and durability make them indispensable for maintaining clean and safe working environments in the automotive, food processing, and warehousing industries. By selecting the right blades, following proper maintenance practices, and partnering