Gum rubber and polyurethane are two different types of rubber squeegee material that are often used for a variety of applications. While both are commonly used in the manufacturing of products, they differ in terms of properties and uses.

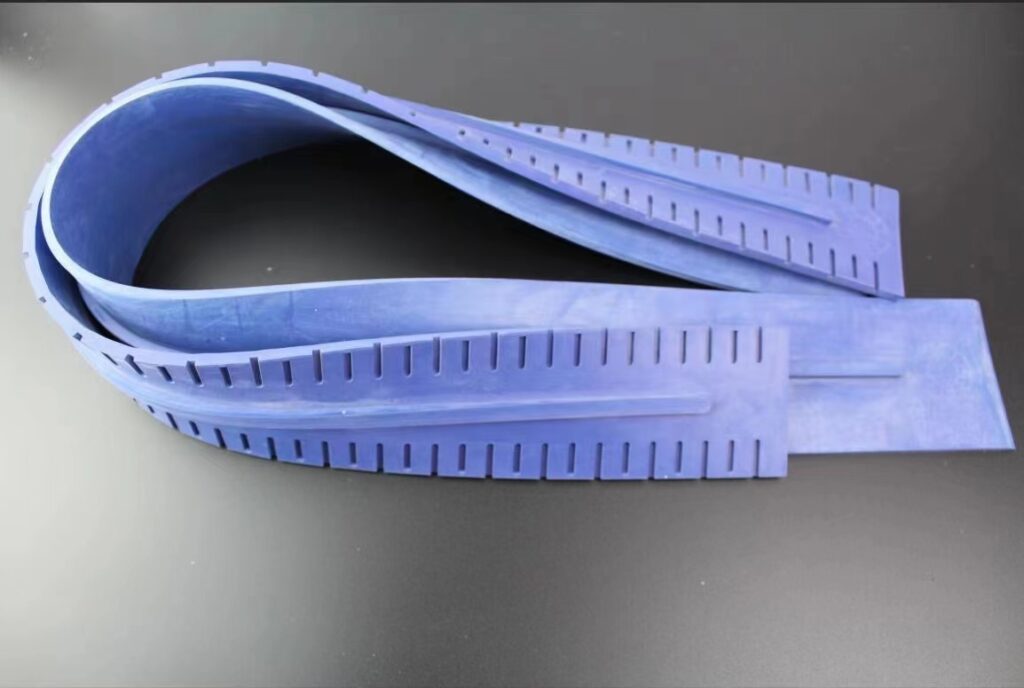

Gum rubber is a type of natural rubber that is primarily used for its elasticity and flexibility

It is often used to make conveyor belts, gaskets, seals, and hoses. It is also used to make natural rubber squeegees, rubber balls, and other rubber-based products. Gum rubber is known for its superior elasticity, good resistance to wear and tear, and excellent tensile strength. It is also resistant to water, oil, and chemicals, making it a great choice for a variety of applications.

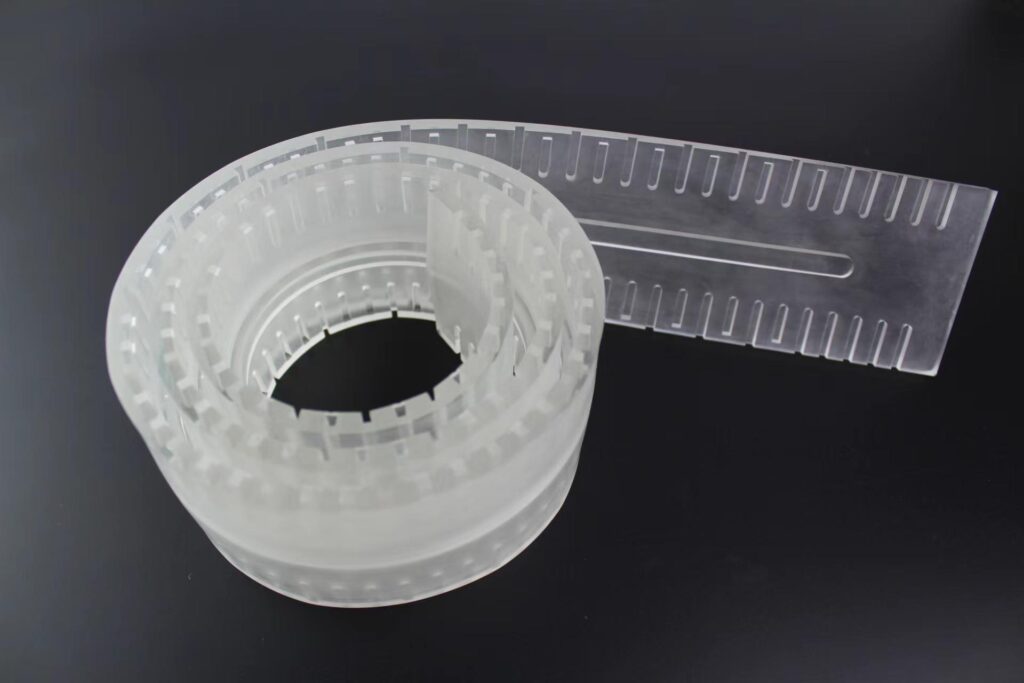

Polyurethane is a synthetic rubber squeegee material that is used for a variety of applications

- It is known for its durability and strength, and is often used to make items such as outdoor rubber squeegees, foam padding, furniture, and automotive parts. It also includes waterproofing and sealing, vibration dampening, cushioning, insulation, sound absorption, and adhesives

- Polyurethane is a versatile material with a broad range of applications. It is widely used in a variety of industries, including janitorial, automotive, construction, electronics, furniture, and medical products. In Janitorial applications, PU is used in to rubber blade squeegee kit. In automotive applications, polyurethane is used to make car door seals, window trim, and insulation. In construction, polyurethane is used to make insulation, sealants, adhesives, and structural components. In electronics, polyurethane is used to make insulation, wire coatings, and electronic components. In furniture, polyurethane is used to make furniture padding, cushions, and upholstery. And in medical products, polyurethane is used to make medical tubing, prosthetics, and orthotics.

- Polyurethane is highly resistant to abrasion, and it is also resistant to water, oil, and chemicals. Unlike gum rubber, polyurethane is not as elastic, but it is still a very versatile material.

The primary difference between gum rubber and PU is the properties of each material. Gum rubber is known for its elasticity and flexibility, while polyurethane is known for its strength and durability. Additionally, gum rubber is naturally resistant to water, oil, and chemicals, while polyurethane is highly resistant to abrasion. Depending on the application, one or both of these materials can be used.