Introduction to Rubber Sheets in Mining

Rubber sheets play a crucial role in mining, providing solutions for various challenges such as abrasion, impact, and corrosion. As the mining industry demands tough, durable materials, rubber sheets are preferred for different applications. This post will explore the uses, benefits, and types of rubber sheets in mining.

Why Rubber Sheets Are Essential in Mining

Mining operations often involve harsh environments where abrasion, impact, and corrosion can lead to equipment failure. Rubber sheets provide protective layers that reduce wear and tear, extending the lifespan of equipment.

- Abrasion Resistance: In mining, equipment and surfaces face constant exposure to abrasive materials like rocks and minerals. Rubber sheets provide excellent abrasion resistance, which prevents wear and tear.

- Impact Resistance: Heavy loads and frequent impacts can damage surfaces and equipment. Rubber sheets absorb impact energy, providing a cushion that prevents significant damage.

- Corrosion Protection: Mines often operate in corrosive environments due to chemicals and moisture. Rubber sheets act as a barrier to corrosive substances, preserving equipment.

For abrasion-resistant and durable rubber sheets for mining, check out NTheron’s range of rubber products.

Types of Rubber Sheets Used in Mining

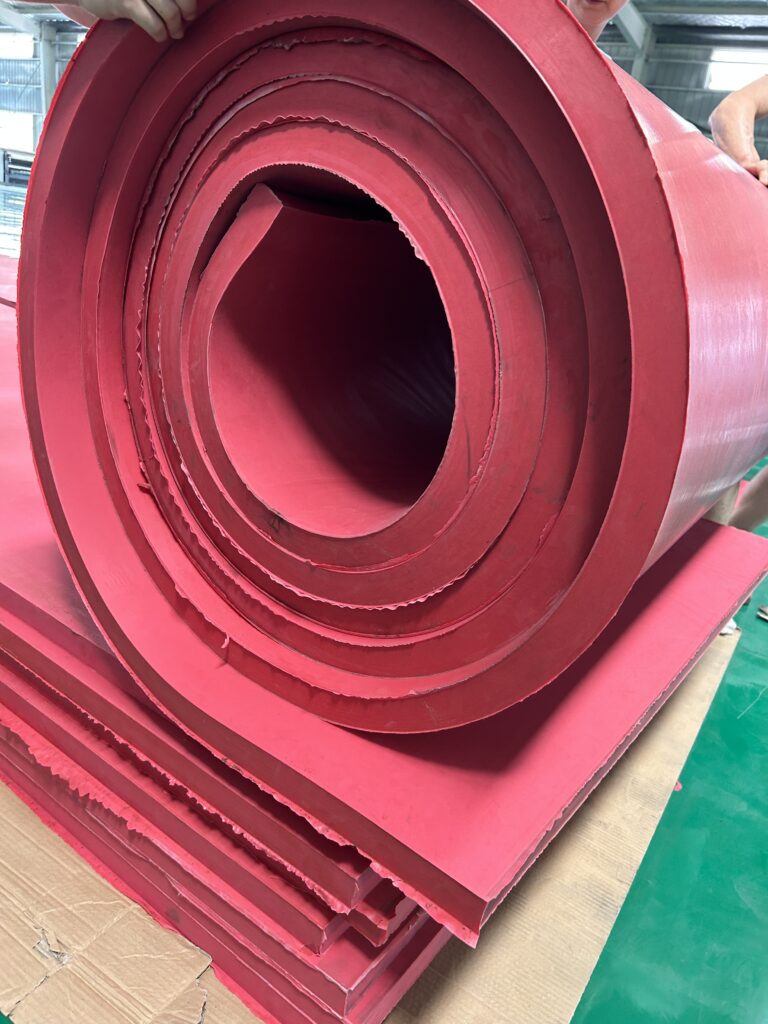

Natural Rubber Sheets

- Highly flexible with great resistance to tear and abrasion.

- Commonly used for lining chutes, hoppers, and other equipment exposed to abrasive materials.

- Offers excellent impact resistance, making it ideal for heavy-duty applications.

Neoprene Rubber Sheets

- Known for its resistance to oil, chemicals, and heat, neoprene rubber is perfect for use in corrosive mining environments.

- Suitable for applications that require resistance to high temperatures or exposure to oils and chemicals.

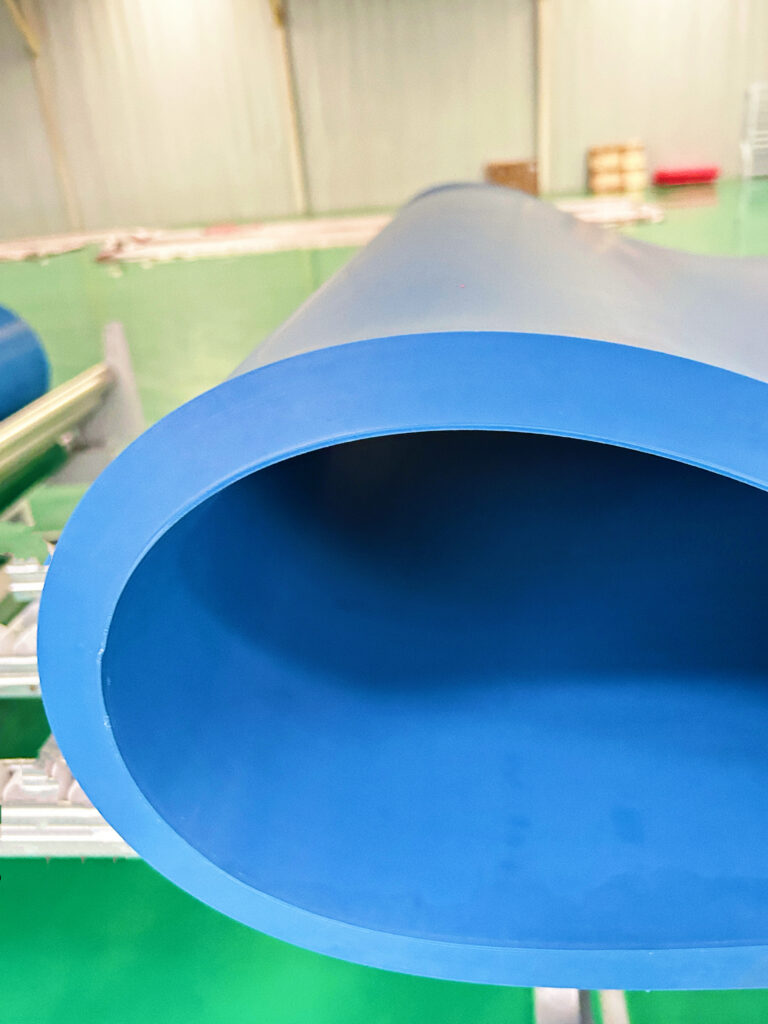

EPDM Rubber Sheets

- Offers excellent resistance to water, weathering, and ozone, making it ideal for use in outdoor mining applications.

- EPDM rubber is highly resistant to harsh weather conditions and is commonly used for sealing and waterproofing purposes in mines.

Butyl Rubber Sheets

- Known for its high impermeability to gases, butyl rubber is perfect for applications in mining areas exposed to gases and chemicals.

- Also used for corrosion-resistant lining in tanks and pipes.

Nitrile Rubber Sheets

- Highly resistant to oils, fuels, and chemicals, nitrile rubber sheets are often used in mining equipment where there’s a risk of oil or chemical exposure.

- Ideal for equipment seals, gaskets, and protective coverings.

NTheron rubber sheet solutions: To explore more about the types of rubber sheets available for mining, visit NTheron’s product page.

Ntheron Limited

Key Applications of Rubber Sheets in Mining

- Conveyor Belts

- Rubber sheets are used as liners for conveyor belts to prevent wear caused by the constant movement of heavy loads.

- Rubber linings enhance the durability of conveyor belts, increasing their operational efficiency and reducing maintenance costs.

- Wear Linings

- Mining equipment such as chutes, hoppers, and cyclones are often lined with rubber sheets to protect them from wear and impact.

- Rubber wear linings are crucial in extending the life of equipment, reducing downtime, and improving productivity.

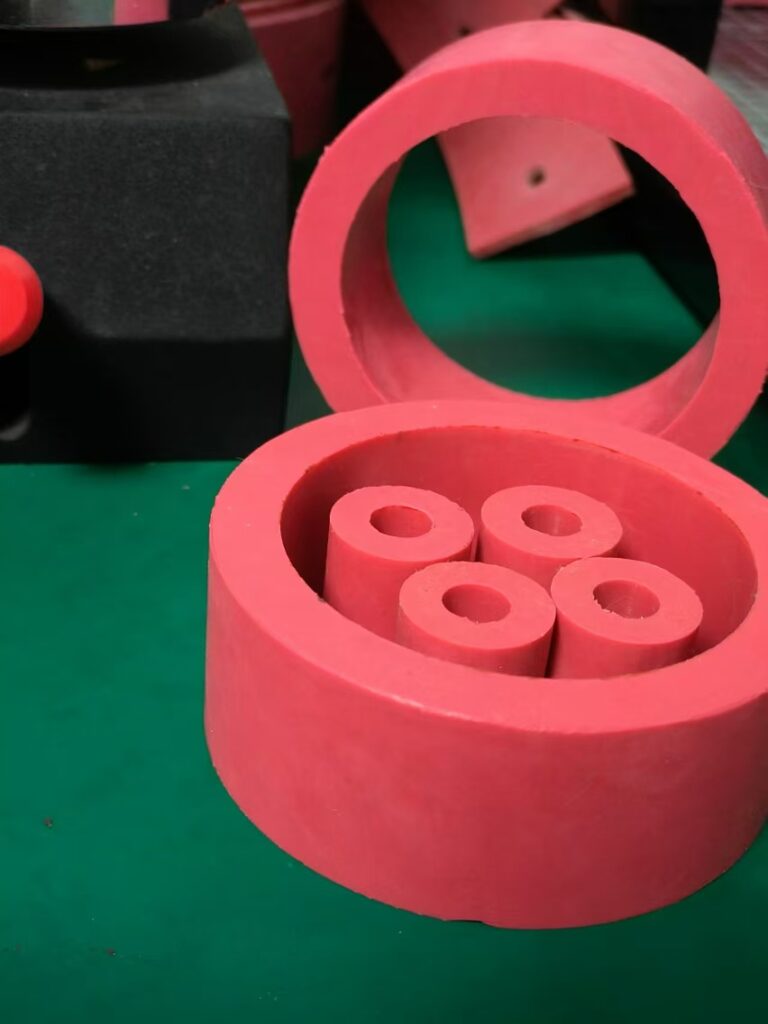

- Sealing and Gasketing

- Rubber sheets are widely used for creating seals and gaskets in mining equipment, preventing leakage and ensuring smooth operations.

- These rubber components help to seal pipelines, tanks, and other mining machinery to prevent leaks and contamination.

- Tank Linings

- Rubber sheets are used to line tanks that store corrosive liquids and chemicals in mining operations.

- This ensures the tank’s longevity by preventing chemical damage and leaks.

For more detailed insights on rubber lining and its benefits in mining, check out this article from Mining Technology.

Benefits of Using Rubber Sheets in Mining

Cost-Effectiveness: Rubber sheets are relatively inexpensive compared to metal or composite alternatives. Their ability to extend the life of mining equipment makes them a cost-effective solution for operations of all sizes.

Noise Reduction: Mining operations are notoriously noisy, and rubber linings help reduce noise pollution by absorbing sound.

Enhanced Safety: By protecting equipment from wear and tear, rubber sheets reduce the risk of equipment failure, ensuring safer working conditions.

Environmentally Friendly: Rubber sheets can be recycled, making them a more environmentally sustainable option for the mining industry.

How to Choose the Right Rubber Sheet for Your Mining Operation

Identify Your Mining Needs: The type of rubber sheet you choose depends on the specific needs of your mining operation. For example, if your equipment is exposed to corrosive chemicals, consider neoprene or butyl rubber. If abrasion resistance is a concern, natural rubber may be the best choice.

Evaluate Durability: Ensure the rubber sheet is durable enough to handle the specific stresses of your operation. Look for products with proven wear resistance, tensile strength, and elongation properties.

Check Temperature Resistance: Depending on your mining location and conditions, temperature resistance can be critical. Materials like neoprene and EPDM are excellent choices for high-temperature environments.

Look for Certifications: Ensure that the rubber sheets you purchase meet industry standards for quality and performance. Certifications such as ISO 9001 are good indicators of reliability.

Conclusion

Rubber sheets are an essential component of modern mining operations, offering protection against wear, impact, and corrosion. NTheron Limited is committed to providing high-quality, durable rubber sheets designed to meet the demands of the mining industry. Whether you need natural rubber for abrasion resistance or neoprene for chemical resistance, NTheron has you covered.

Call to Action: Explore NTheron’s comprehensive range of rubber sheets for mining here.